Like a cat with nine lives, my iBOT wheelchair keeps cheating death. For those of you not in the know, the iBOT is the most incredible wheelchair ever built. Unfortunately, due to bureaucratic red tape and insurance company cold-heartedness, this wheelchair is no longer manufactured or sold. A couple of years ago, the previous manufacturer,… Continue reading My iBOT Gets Recharged

Tag: iBot Wheelchair

The iBot Lives!

This is the news we’ve all been waiting for. A little company called Toyota will partner with DEKA to develop and manufacture the next generation of iBot. Read the press release here, and be sure to watch the video embedded in the story. To see video of my iBot in action, click here.

The Social Psychology Implications of iBot Stair Climbing

Yeah, you read that right. This subject is better suited for a PhD dissertation, but instead I’ll tackle it in a single blog post. On Saturday night Kim and I went out to dinner with our friends Deb and Steve at the Snow Squall, a local bar and restaurant that we absolutely love. I made… Continue reading The Social Psychology Implications of iBot Stair Climbing

Save the IBot Update: the FDA Gives Us Some Good News

You might call it an early Christmas present. As I indicated in my previous iBot update, the FDA held a hearing on December 12 to consider DEKA’s petition to change the iBot medical classification. As I wrote in that post: “…The iBot needs a new manufacturer. But first, the regulatory environment must be improved. DEKA… Continue reading Save the IBot Update: the FDA Gives Us Some Good News

Save the IBot Update and My Trip to DEKA

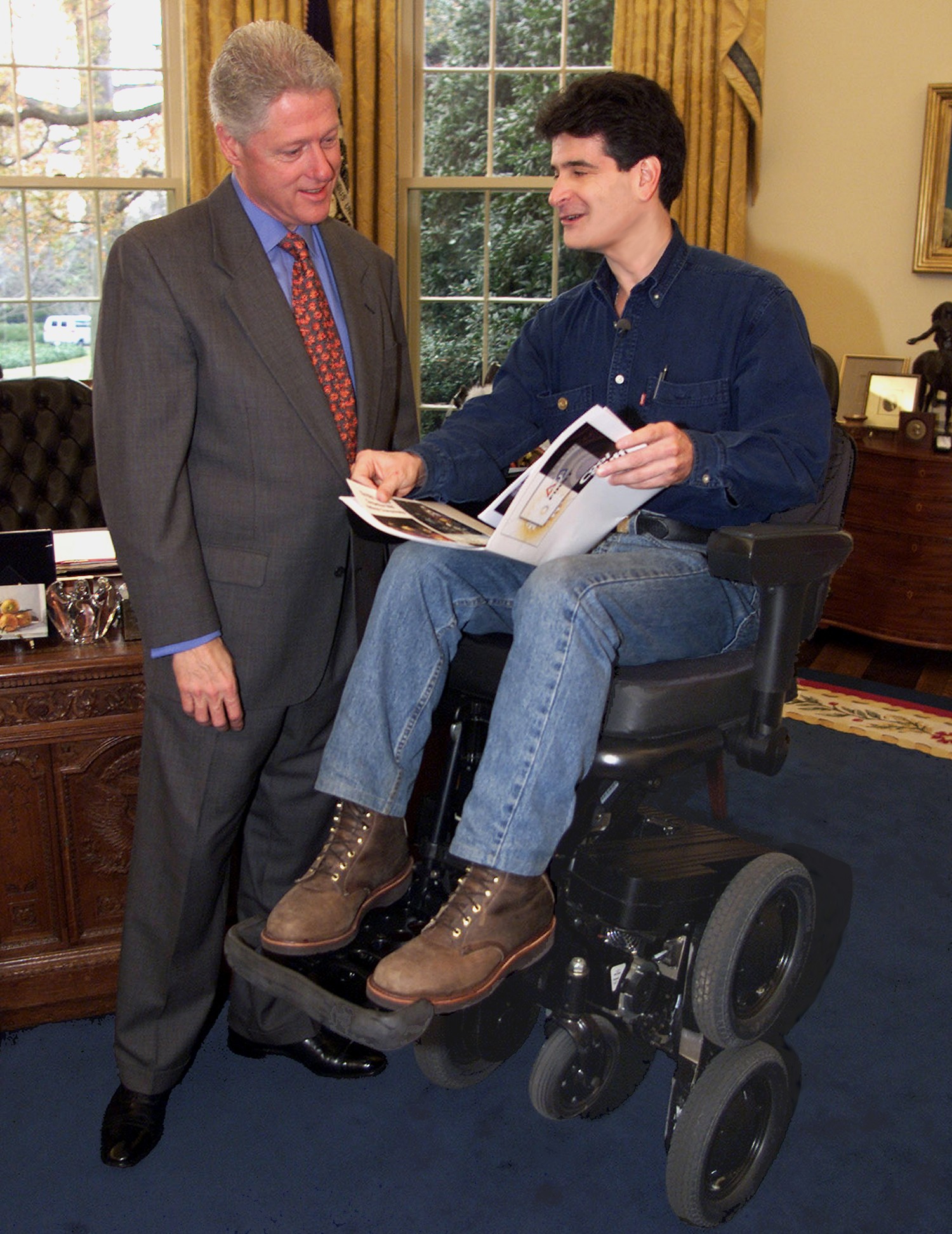

This picture shows Bill Clinton and Dean Kamen in the office of the president. Kamen is on his iBot. (Photo credit: Wikipedia) The story of the iBot is a potentially heartbreaking one. This exceptional wheelchair, which can climb stairs, navigate difficult terrain in four-wheel-drive mode, and elevate its user up to eye level with standing… Continue reading Save the IBot Update and My Trip to DEKA

Bahamas 2012, #7: Taking the iBot to the Bahamas

I put together a short video showing how the iBot performed in the Bahamas. Check back in the coming days for my last two posts about our wonderful vacation. Enjoy. Click for next post: Bahamas 2012, #8: Getting Home Click for previous post: Bahamas 2012, #6: More Stuff We Did Here are my other iBot videos: Taking… Continue reading Bahamas 2012, #7: Taking the iBot to the Bahamas

Save the iBot Update

As you may already know, the iBot, this life-changing mobility device, is no longer being manufactured. Why? It’s because of a complex set of circumstances generally having to do with too much government red tape and a pervasive attitude that disabled people do not deserve to live highly engaged lives – getting us from bedroom… Continue reading Save the iBot Update

Taking the iBot to Crotched Mountain

Kim and I recently took a hike in the woods. “But Mitch, aren’t you in a wheelchair?” Yes. Yes I am. Please visit the Crotched Mountain Foundation to learn more about their accessible hiking trails. Please visit www.savetheiBot.org for more information about how to help save this life-changing wheelchair. Click here (and then scroll down)… Continue reading Taking the iBot to Crotched Mountain

Neighborhood Excursion #1 – Bug Light Park

I posted here and here about our recent move to a more walkable neighborhood. I plan to make a series of slideshows and/or videos where I share different excursions that I take in my new neighborhood, using my iBot wheelchair. Here is the first such slideshow, my excursion to Bug Light Park (not Bud Light).… Continue reading Neighborhood Excursion #1 – Bug Light Park

For Every 100 People That Walk by Me When I'm in iBot Balance Mode…

… I bet 30 of them think something like, “Wow, that is strange, but I’m going to carry on as if it’s nothing interesting at all. Must…not…reveal…amazement.” And they’ll say this to themselves for a wide variety of reasons: too cool, too shy, too polite, fugitive from justice. When I’m zipping around in balance mode in… Continue reading For Every 100 People That Walk by Me When I'm in iBot Balance Mode…